Reference

ALUMINIUM PREMIUM CASTINGS

Aluminium and magnesium castings for aerospace and automotive industries are produced on IMF plants specifically studied to allow highly specialised personnel to accomplish the complex operations for pattern preparation, core setting, etc.

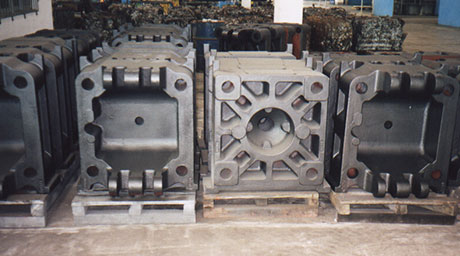

CASTINGS FOR PLASTIC INDUSTRY

Because of their massive size, these castings are produced in flasks with different levels of automation.

CASTINGS FOR RAILWAY CROSSINGS

Manganese steel castings for railway crossing have been produced for long time with IMF mixers and moulding lines. These castings were traditionally 5 to 10 meters long, nowadays with the coming of high speed trains, these castings are 11 to 12 meters long. IMF has produced a moulding line dedicated to these really impressive sizes.

CASTINGS FOR RAILWAY INDUSTRY

Side frames and bolsters for railway carriages are steel castings produced on large moulding installations such as Fast Loops with a high production rate that can reach 8 moulds per hour.

These installations can work with flasks or flaskless and mould plates reach size 1800 x 3400 mm.

The moulds produced can weigh up to 8 tons each. IMF has accrued a wide experience in this field, both in studying and manufacturing installations, in the knowledge of the associated metallurgy and of the pattern design methods.

CASTINGS FOR WIND ENERGY SECTOR

Parts of wind TURBINES for renewable energy, including large and complex rotor hubs , are produced with IMF mixers and sand reclamation plants.

COUNTER-WEIGHTS

Counter-weights for fork lifts and cranes are particularly suitable for production on IMF moulding lines. Flaskless moulding requires a very low sand to metal ratio which provides a saving in sand , and the positive effects of natural thermal reclamation of the sand by the hot metal.

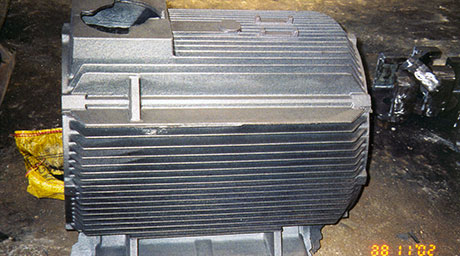

DISCHARGE MANIFOLDS FOR HIGH-PERFORMANCE MOTORS

ELECTRIC MOTOR FRAMES

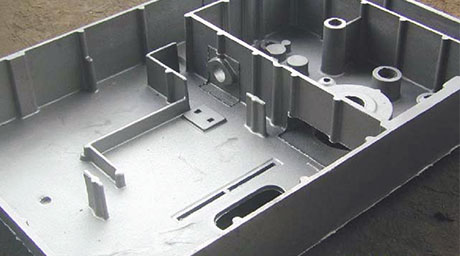

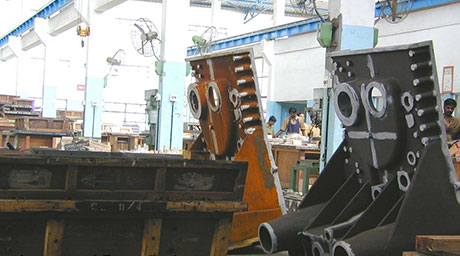

FRAMES FOR MACHINE TOOLS

FRAMES FOR TEXTILE MACHINES AND THEIR COMPONENTS

They are produced both in flasks and flaskless moulds according to the size and to the material of the piece.

LARGE DIESEL ENGINES

Cylinder blocks for railway, naval and energy sectors are produced with a traditional system or by sectors on the floor or in pits with an IMF mixer.

LARGE MECHANICAL CASTINGS

Large castings for the most varied sectors are produced on the floor or in pits with mobile machines. These castings, up to 7 tons are more and more produced on automatic installations with moulding plate size exceeding 3×4 m.

PROPELLERS FOR MARINE SECTOR

Propellers weighing a few kilo for small boats or up to 100 tons for large ships are produced with IMF mixers and sand reclamation plants. Most of the small to medium size propellers are produced on high productivity Fast Loop type moulding plants.

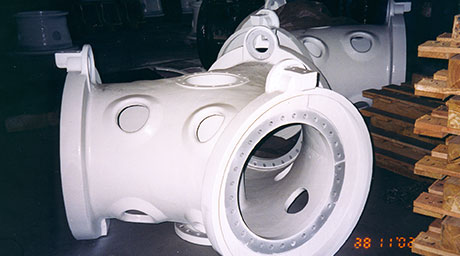

PUMPS

They are produced in all metals and all sizes for the most varied applications. These types of foundries produce pumps with a diameter varying from a very small up to 3 meters.

VALVES

These are produced on Fast Loop lines in China, India, USA, Australia, Dubai, Italy, South America and Chile. These valves to be used in all the applications requiring very high quality castings such as petroleum and gas drilling, high-pressure gas installation, nuclear power generation.

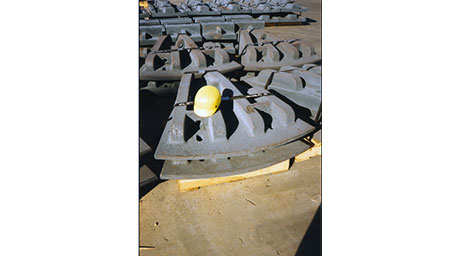

WEAR PART CASTINGS

IMF can count among its customers all the major producers of this type of castings in all continents. This sector registers an increasing request for automation of the production of larger and larger flasks.